The Hitachi "Global Deployment of Mining Solution Business Powered by ICT" delves into the integration of Information and Communication Technology (ICT) within the mining sector, aiming to elevate operational efficiency and productivity. It delineates the evolution of Fleet Management Systems (FMS), progressing from rudimentary vehicle dispatch systems to comprehensive operational support systems. These sophisticated systems now oversee critical aspects such as blasting plans, material quality, safety protocols, and the condition of fleet vehicles.

Emphasizing the pivotal role of data handling and analysis, the article underscores the burgeoning data volume generated at mine sites. It stresses the necessity of leveraging synergies within Hitachi's framework to devise systems adept at efficiently and accurately collecting this data. Such systems, it contends, are instrumental in optimizing mining operations.

Furthermore, the article broaches the subject of cloud technology's significance in mining operations, particularly in the context of remote control centers. It cites the successful trial of Wenco’s FMS, operated via cloud-based infrastructure at a Canadian mine site. This trial showcased notable enhancements in operational response times, shedding light on operational intricacies.

Additionally, the article underscores the imperative for tools capable of analyzing vast datasets from myriad perspectives to synchronize upstream and downstream processes. It cites the collaborative development of an analysis system utilizing Business Intelligence (BI) tools in conjunction with Hitachi, Ltd.

Concluding, the article underscores the integration of FMS and other ICT advancements into machinery, envisaging a future where machines become smarter and adept at supporting human endeavors, particularly in production and safety domains. It accentuates Hitachi's comprehensive prowess in the mining industry and its aspirational trajectory to transcend its conventional role as a mining machinery vendor, aspiring to evolve into a multifaceted solutions provider.

In essence, the article underscores the paramountcy of ICT in augmenting operational efficiency and productivity within the mining domain, particularly through the amalgamation of FMS and cloud technology. It underscores the indispensability of data analysis and the imperative of developing analytical tools proficient in optimizing mining operations.

- what are the benefits of deploying mining solutions powered by ict

The benefits of deploying mining solutions powered by ICT include:

- Improved Efficiency: ICT integration enables real-time monitoring and management of mining operations, allowing for more efficient allocation of resources and better decision-making12.

- Enhanced Safety: ICT-based solutions can improve safety by providing real-time data on equipment performance, enabling predictive maintenance, and enhancing operator visibility through advanced sensors and monitoring systems12.

- Increased Productivity: ICT solutions can optimize mining operations by streamlining processes, reducing downtime, and improving communication among stakeholders, leading to increased productivity12.

- Better Resource Allocation: ICT integration enables data-driven decision-making, allowing for more effective allocation of resources and better management of mining operations12.

- Reduced Costs: ICT solutions can reduce costs by optimizing energy consumption, minimizing waste, and improving maintenance practices, leading to lower operational expenses12.

- Improved Customer Satisfaction: ICT-based solutions can enhance customer satisfaction by providing real-time updates on equipment performance, improving communication, and ensuring timely maintenance and support12.

- Competitive Advantage: Deployment of ICT-powered mining solutions can provide a competitive advantage by enabling companies to operate more efficiently, effectively, and sustainably, setting them apart from competitors12.

- Environmental Sustainability: ICT solutions can contribute to environmental sustainability by reducing energy consumption, minimizing waste, and improving resource utilization, aligning with the industry's growing focus on environmental responsibility12.

- Data-Driven Decision Making: ICT integration enables data-driven decision-making, allowing companies to make informed decisions based on real-time data and analytics, rather than relying on intuition or historical trends12.

- Future-Proofing: Deployment of ICT-powered mining solutions can future-proof mining operations by preparing them for the increasing demands of digital transformation, automation, and data-driven decision-making12.

These benefits highlight the importance of integrating ICT into mining operations to enhance efficiency, productivity, safety, and sustainability, ultimately contributing to the long-term success of mining companies

- what are some specific ict technologies used in mining solutions

Some specific ICT technologies used in mining solutions include:

- Cloud Technology: Cloud technology is used to manage and analyze large amounts of data generated by mining operations. This includes the use of cloud-based systems for fleet management, remote monitoring, and data analytics12.

- Big Data Analytics: Big data analytics is used to analyze large amounts of data from various sources, such as sensors, equipment, and maintenance records, to optimize mining operations and improve efficiency12.

- Internet of Things (IoT): IoT technology is used to connect and monitor mining equipment, enabling real-time monitoring and control of operations12.

- Artificial Intelligence (AI): AI is used to analyze data and make predictions about equipment performance, maintenance needs, and potential issues, enabling proactive maintenance and optimization12.

- Machine Learning (ML): ML is used to develop predictive models that can identify patterns in data and make predictions about future equipment performance and maintenance needs12.

- Autonomous Systems: Autonomous systems, such as autonomous haulage systems (AHS), are being developed to improve safety and efficiency in mining operations12.

- Sensor Technology: Sensor technology is used to monitor equipment performance and detect potential issues before they become major problems12.

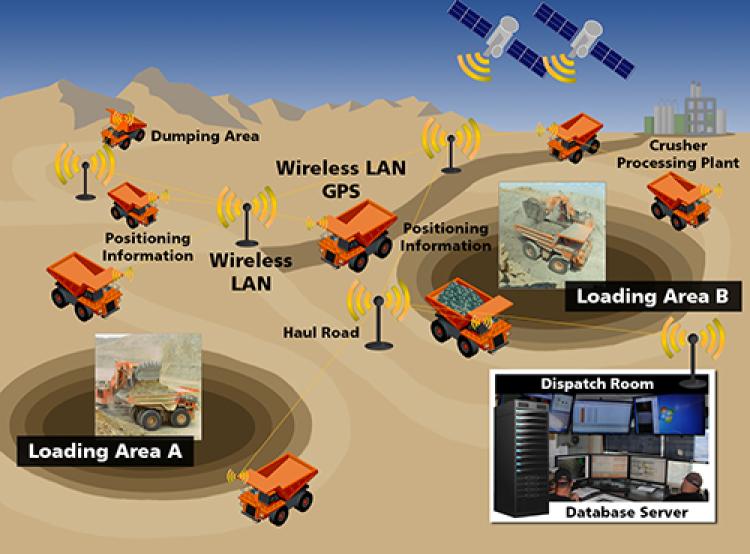

- GPS and Location-Based Services: GPS and location-based services are used to track equipment location and movement, enabling more efficient routing and dispatching12.

- Wireless Communication: Wireless communication technologies, such as Wi-Fi and cellular networks, are used to enable remote monitoring and control of mining operations12.

- Business Intelligence (BI) Tools: BI tools are used to analyze and visualize data, enabling data-driven decision-making and optimization of mining operations12.

These ICT technologies are integrated into various systems, such as fleet management systems (FMS), to enhance operational efficiency, safety, and productivity in the mining industry

- how do ict technologies improve productivity in the mining industry

ICT technologies improve productivity in the mining industry by enhancing operational efficiency, reducing costs, and increasing the overall effectiveness of mining operations. Some key ways ICT technologies contribute to improved productivity include:

- Real-time Monitoring and Control: ICT systems enable real-time monitoring and control of mining operations, allowing for more efficient allocation of resources and better decision-making12.

- Predictive Maintenance: ICT-based predictive maintenance systems can detect potential issues before they become major problems, reducing downtime and increasing overall productivity12.

- Optimized Fleet Management: ICT systems optimize fleet management by providing real-time data on equipment performance, enabling more efficient routing and dispatching, and reducing fuel consumption12.

- Improved Safety: ICT technologies improve safety by providing real-time data on equipment performance, enabling more effective safety monitoring, and reducing the risk of accidents12.

- Enhanced Data Analysis: ICT systems enable advanced data analysis, allowing for more effective decision-making and optimization of mining operations12.

- Automation and Automation Support Systems: ICT technologies support automation in mining operations, such as autonomous haulage systems (AHS), which can improve efficiency and reduce labor costs12.

- Cloud Technology: Cloud technology enables remote monitoring and control of mining operations, allowing for more efficient management and optimization of operations12.

- Big Data Analytics: Big data analytics enables the analysis of large amounts of data generated by mining operations, allowing for more effective decision-making and optimization of operations12.

- Artificial Intelligence (AI): AI is used in mining operations to analyze data and make predictions about equipment performance, maintenance needs, and potential issues, enabling proactive maintenance and optimization12.

- Integration of Systems: ICT systems integrate various systems and technologies, such as fleet management, maintenance, and safety systems, to provide a comprehensive view of mining operations and enable more effective decision-making12.

These ICT technologies contribute to improved productivity in the mining industry by enhancing operational efficiency, reducing costs, and increasing the overall effectiveness of mining operations

- what are some examples of ict technologies used in mining solutions to improve productivity

Some examples of ICT technologies used in mining solutions to improve productivity include:

- Cloud Technology: Cloud technology is used to manage and analyze large amounts of data generated by mining operations, enabling more efficient and centralized management of mine operations12.

- Big Data Analytics: Big data analytics is used to analyze large amounts of data from various sources, such as sensors, equipment, and maintenance records, to optimize mining operations and improve efficiency12.

- Artificial Intelligence (AI): AI is used in mining operations to analyze data and make predictions about equipment performance, maintenance needs, and potential issues, enabling proactive maintenance and optimization12.

- Machine Learning (ML): ML is used to develop predictive models that can identify patterns in data and make predictions about future equipment performance and maintenance needs12.

- Autonomous Systems: Autonomous systems, such as autonomous haulage systems (AHS), are being developed to improve safety and efficiency in mining operations12.

- Sensor Technology: Sensor technology is used to monitor equipment performance and detect potential issues before they become major problems12.

- GPS and Location-Based Services: GPS and location-based services are used to track equipment location and movement, enabling more efficient routing and dispatching12.

- Wireless Communication: Wireless communication technologies, such as Wi-Fi and cellular networks, are used to enable remote monitoring and control of mining operations12.

- Business Intelligence (BI) Tools: BI tools are used to analyze and visualize data, enabling data-driven decision-making and optimization of mining operations12.

- Integration of Systems: ICT systems integrate various systems and technologies, such as fleet management, maintenance, and safety systems, to provide a comprehensive view of mining operations and enable more effective decision-making12.

These ICT technologies contribute to improved productivity in the mining industry by enhancing operational efficiency, reducing costs, and increasing the overall effectiveness of mining operations

- what are some examples of automation technologies used in mining solutions

Some examples of automation technologies used in mining solutions include:

- Autonomous Haulage Systems (AHS): Autonomous haulage systems are being developed to improve safety and efficiency in mining operations. These systems use advanced sensors and navigation systems to enable autonomous operation of haulage vehicles, reducing the need for human intervention and improving overall productivity12.

- Autonomous Loaders: Autonomous loaders are another example of automation technology being applied in mining. These machines use advanced sensors and navigation systems to operate independently, improving efficiency and reducing labor costs12.

- Simulation Technology: Simulation technology is used in mining to support product development and testing. This involves creating digital models of mining equipment and simulating various scenarios to test performance and optimize design12.

- Cloud Technology: Cloud technology is used in mining to enable remote monitoring and control of mining operations. This includes the use of cloud-based systems for fleet management, remote monitoring, and data analytics12.

- Big Data Analytics: Big data analytics is used in mining to analyze large amounts of data generated by mining operations. This includes the use of advanced analytics and machine learning algorithms to optimize mining operations and improve efficiency12.

- Predictive Maintenance: Predictive maintenance is used in mining to detect potential issues before they become major problems. This involves using advanced sensors and data analytics to monitor equipment performance and predict when maintenance is required12.

- Autonomous Drilling Systems: Autonomous drilling systems are being developed to improve efficiency and safety in mining operations. These systems use advanced sensors and navigation systems to enable autonomous operation of drilling equipment, reducing the need for human intervention and improving overall productivity12.

- Autonomous Crushing Systems: Autonomous crushing systems are another example of automation technology being applied in mining. These machines use advanced sensors and navigation systems to operate independently, improving efficiency and reducing labor costs12.

- Autonomous Transportation Systems: Autonomous transportation systems are used in mining to transport materials and equipment. These systems use advanced sensors and navigation systems to operate independently, improving efficiency and reducing labor costs12.

- Autonomous Material Handling Systems: Autonomous material handling systems are used in mining to handle and transport materials. These systems use advanced sensors and navigation systems to operate independently, improving efficiency and reducing labor costs12.

These automation technologies are used in various mining applications, including open-pit mining, underground mining, and quarrying, to improve efficiency, reduce costs, and enhance safety

- what are some challenges in implementing automation technologies in the mining industry

Implementing automation technologies in the mining industry poses several challenges. Some of the key challenges include:

- Integration with Existing Systems: Integrating automation technologies with existing systems, such as fleet management systems, can be complex and require significant IT resources12.

- Data Quality and Availability: Ensuring the quality and availability of data from various sources, such as sensors and equipment, is crucial for effective automation. This includes addressing issues like data latency, accuracy, and consistency12.

- Cybersecurity: Protecting automation systems from cyber threats is critical, as they can compromise the safety and security of mining operations. This includes implementing robust security measures and conducting regular security audits12.

- Operator Training and Education: Automation technologies require specialized training and education for operators to effectively utilize them. This includes addressing issues like operator familiarity with new technologies and the need for ongoing training12.

- Cost and ROI: Implementing automation technologies can be costly, and companies must be able to demonstrate a clear return on investment (ROI) to justify the expense. This includes addressing issues like the cost of implementation, maintenance, and upgrades12.

- Regulatory Compliance: Automation technologies must comply with relevant regulations and standards, such as those related to safety and environmental impact. This includes addressing issues like regulatory approvals and compliance with industry standards12.

- Scalability: Automation technologies must be scalable to accommodate the needs of growing mining operations. This includes addressing issues like the ability to handle increased data volumes and the need for flexible systems12.

- Maintenance and Support: Automation technologies require ongoing maintenance and support to ensure they continue functioning effectively. This includes addressing issues like the availability of spare parts, technical support, and maintenance schedules12.

- Communication and Collaboration: Effective communication and collaboration among stakeholders, including operators, maintenance personnel, and management, are crucial for successful automation implementation. This includes addressing issues like communication protocols, data sharing, and collaboration tools12.

- Change Management: Implementing automation technologies often requires significant changes to existing processes and procedures. This includes addressing issues like resistance to change, cultural shifts, and the need for ongoing communication and training12.

These challenges highlight the importance of careful planning, execution, and ongoing support for successful automation implementation in the mining industry

- COCLUSION

In conclusion, the article sheds light on the transformative potential of Information and Communication Technology (ICT) within the mining sector, emphasizing its role in enhancing operational efficiency and productivity. It traces the evolution of Fleet Management Systems (FMS) into comprehensive operational support systems, capable of overseeing critical aspects ranging from blasting plans to fleet vehicle conditions.

Central to this narrative is the imperative of effective data handling and analysis, considering the escalating volume of data generated at mining sites. Leveraging synergies within Hitachi's ecosystem is deemed essential to devise systems proficient in collecting and utilizing this data to optimize mining operations.

Moreover, the article underscores the significance of cloud technology, exemplified by the successful trial of Wenco’s FMS operated via cloud-based infrastructure. This trial not only showcased operational enhancements but also illuminated the potential of cloud technology in mining operations.

Furthermore, the article highlights the necessity for analytical tools capable of synchronizing upstream and downstream processes through the collaborative development of analysis systems utilizing Business Intelligence (BI) tools.

In essence, the article foresees a future where the integration of FMS and other ICT advancements into machinery renders them smarter, supporting human endeavors in production and safety realms. It underscores Hitachi's comprehensive prowess in the mining industry, aiming to transcend its conventional role and evolve into a multifaceted solutions provider.

Ultimately, the article underscores the paramountcy of ICT in augmenting efficiency and productivity within the mining domain. It emphasizes the importance of data analysis and the imperative of developing analytical tools proficient in optimizing mining operations. Through the amalgamation of FMS and cloud technology, ICT emerges as a cornerstone for driving operational excellence, safety, and sustainability in the mining industry.